Sourcing an inkjet date coder should be a simple task but some inkjet date coder technologies are so complicated, you might find yourself getting too absorbed into the details of the coder and overlook another aspect of product coding, the ink itself. Inks really make or break the product coding application, so, having a better understanding of what makes inkjet inks work for applications might help you get exactly what you want.

WHAT CONSTITUTES AN INKJET INK?

1. RESIN

A resin provides the finished ink appearance and is responsible for dispersing “carrying” the colorant. Resins provide properties like adhesion, abrasion-resistance, and ultra-violet resistance which is referred to as lightfastness.

2. COLORANT

There are two types of colorants that may be used in inkjet inks: Dye and pigment colorants.

A dye colorant is transparent in appearance, and does not provide strong lightfastness or heat resistant properties. Dye colorant inks are good for products that remain indoors and are out of extreme weather. What makes a dye colorant ink work well in inkjet coders is that the dye colorant stays in solution and does not require shaking or stirring. Dye inks are economical to use and suitable for printing onto many substrates such as paperboard packaging, plastics, and metals.

Pigment colorants are opaque in appearance and offer good lightfastness and weather resistance. Pigment inks provide the least amount of risk for ink transfer, when two surfaces come together such as a plastic material on a roll or spool and one printed image transfers on the mating surface. Pigment colorant does not stay suspended within the ink so it is important to agitate the ink volume to prevent the pigment colorant from falling out of suspension. You may recognize this by some printers requiring you to shake the ink or the need to constantly stir the ink.

Since pigment colorant inks are opaque, they are suitable for coding dark color substrates to provide a contrasting code, such as a white code on a brown beer bottle or cola beverage container product. Pigment colorant inks are also good for products that are kept outdoors, and for products printed before being spooled.

3. SOLVENT

Solvent enables the resin-colorant mixture to be transferred to the material substrate during printing. Solvent is what makes the ink dry as fast as it does. You might think, why not always use the fastest drying ink? Selection of what fast-drying solvent to use comes with a trade-off impacting performance, price and workplace environment.

Below: Fast-drying solvent inks are recommended for non-porous materials such as this metalized film.

The higher performing inks that use 2-Butanone (MEK) solvent delivers the fastest dry times but typically cost more than inks that contain an alcohol-based solvent such as ethanol. The difference between these two inks in respective order could be 1-2 seconds dry time versus 2-5 seconds dry time on non-porous surfaces. It is important to look ahead of the production line where products are inkjet coded and understand how important dry time really is. It could mean significant savings in your ink purchases.

Inkjet date coders that use faster drying inks typically require more care than those using slower drying inks. Be prepared to clean the print head nozzle before starting a production run if you plan to use fast-dry solvent inks. Continuous Inkjet (CIJ) coders require a cleaning procedure to wash the print head with MEK solvent before or after use. This cleaning solvent will need to be disposed of correctly, meaning your company will need to have handling procedures in place if you use a CIJ inkjet coder.

Below: Redimark T602K ink is ideal for date coding polypropylene film.

4. ADDITIVES

Additives in the ink define the ink characteristics and differentiate the value from one supplier to another. Additives give ink flexibility, aid flow, improve dot formation and provide pigment stability. When you’ve had a good experience using one ink over another, it is mostly a result of the additives in the ink that make it a great match for your application.

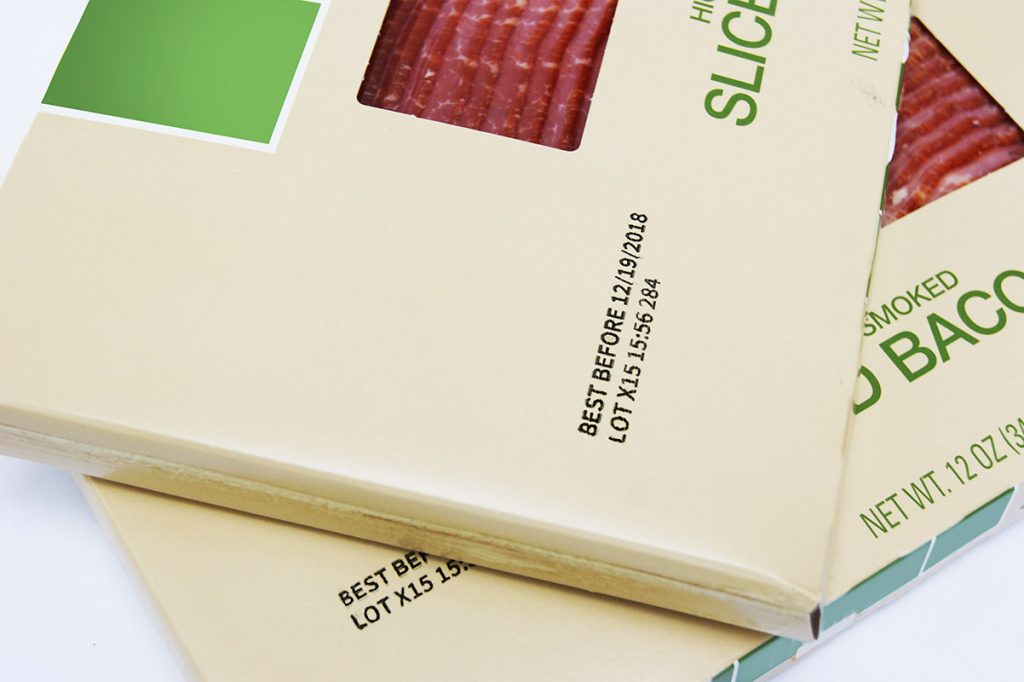

Below: While paperboard is porous, the varnish coating on this folding carton for UV protection renders it a non-porous substrate meaning a fast-drying solvent ink is the right choice here.

High-performance inkjet date coder and ink selection should not be mutually exclusive. No longer should you settle on using CIJ technology in order to use fast-drying inks. You can now benefit from the latest inkjet coder technology and experience great fast-dry ink performance with the introduction of thermal inkjet (TIJ) technology. TIJ is perfect for small character product coding of Fast-Moving Consumer Goods (FMCG’s).

The Redimark TC12 thermal inkjet date coder offers superior print quality and fast-drying cartridge inks for many types of non-porous packaging materials. It is remarkably simple to use, maintenance and mess free.

Have questions on any packaging topics? Email [email protected].

ABOUT DEAN HORNSBY

Dean is passionate about sharing his deep knowledge about packaging and perfectly printed date codes. In his more than 25 years in the Fast-Moving Consumer Goods (FMCG) industry, Dean has done and seen it all; from engineering to plant automation to vision and coding systems.