TRY BEFORE YOU BUY

All Redimark TC12 thermal inkjet printers come with a free short-run, 27ml ink cartridge, allowing you to test an ink type before you even have to buy your first XL, 47ml ink cartridge, with 40% more ink.

The starter-sized, short-run cartridge is perfect to do a limited production run to test:

- Ink dry time

- Ink adhesion

- Contrast and saturation

- Print placement options

NO NEED TO GUESS, WE MAKE IT SIMPLE

Check out our ink performance matrixes below to see how each of our inks preform on different substrates. Choose the right balance between ink dry time, adhesion, print darkness, character definition, and print idle time for your unique production and print needs.

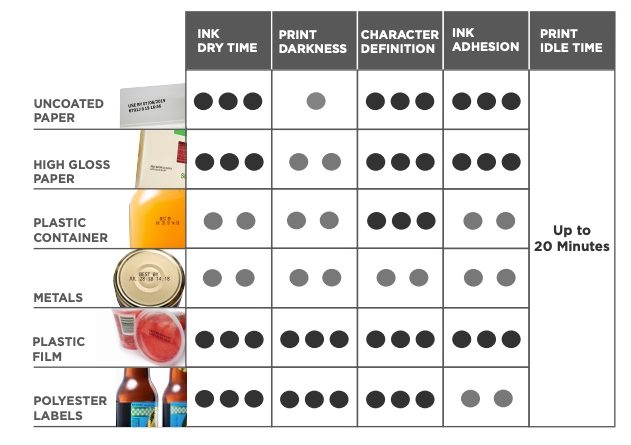

T801K INK PERFORMANCE MATRIX

T801K INK

- Ideally suited for semi-porous to non-porous materials like aluminum, film, foil, HDPE, laminate, LDPE, metal, PET, plastic, PP, PS, PVC, steel, tin

- 1-2 seconds typical dry time

- Advantages: Very fast dry time, fine line quality, higher contrast on plastics

- $135 per XL cartridge, discount for orders of five or more

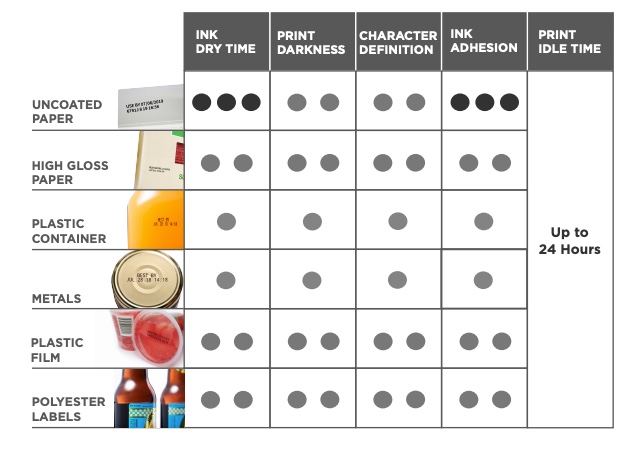

T602K INK PERFORMANCE MATRIX

T602K INK

- Ideally suited for porous to semi-porous material like cardboard, kraft paper, paperboard coated, paperboard uncoated, paperboard SBS

- 2-5 seconds typical dry time

- Advantages: Long print idle time, medium dot spread, more affordable

- $115 per XL cartridge, discount for orders of five or more

WHAT IT MEANS AND WHT IT MATTERS:

Print idle time/ decap time – The amount of time an ink cartridge can be left uncapped before the solvent will start drying out. If too much solvent dries out, the ink will be too thick to get through the nozzles leaving that cartridge unusable. Worried about ink cartridges being capped on the floor every time not in use? Try the T602K ink with a 24 our print idle time.

Ink dry time – The amount of time it takes the ink to dry after making contact with the package. Ink usually dries faster on porous materials than non-porous materials. Printing on metal, plastic, high gloss paper, or polyester labels? The T801K ink, with a 1-2 second dry time, is recommended.

Print darkness – The depth of shade of the print and level of contrast. Looking for a print that really pops or printing on plastic film or polyester labels? Try the T801K ink. Printing on uncoated or high-gloss paper, metal, or plastic containers? The T602K ink will serve you well and save you a few dollars.

Character definition – The sharpness of the lines within a print. A well-defined print is easier to read and great if using small fonts. For the crispest print, especially on plastic, try the T801K ink.

Ink adhesion – How well the ink sticks to surfaces and substrates. A fast dry-time and high ink adhesion can prevent smudging, smearing, and prints wiping off. If you are printing on cardboard, kraft paper, paperboard coated, paperboard uncoated, or paperboard SBS the T602K ink should work well. T801K ink will help prevent prints from streaking or wiping off on aluminum, film, foil, HDPE, laminate, LDPE, metal, PET, plastic, PP, PS, PVC, steel, and tin.