MARKING SYSTEM AND INK

The product code is printed directly on the coated label, prior to the shrink sleeve transfer to the bottle, with the Redimark TC12 thermal inkjet date coder using T801K ink.

The T801K ink, with a 1-2 second dry time, prints on most coated or uncoated labels or shrink sleeves. Stretch and shrink sleeve, plastic or polyester labels, with a semi-porous to non-porous surface, are emerging as a desirable form of CPG product labeling due to the 360-degree message branding that helps the product attain high-impact presentation on the store shelf.

T801K ink provides sharp contrast and fine line quality for an extra crisp clear print.

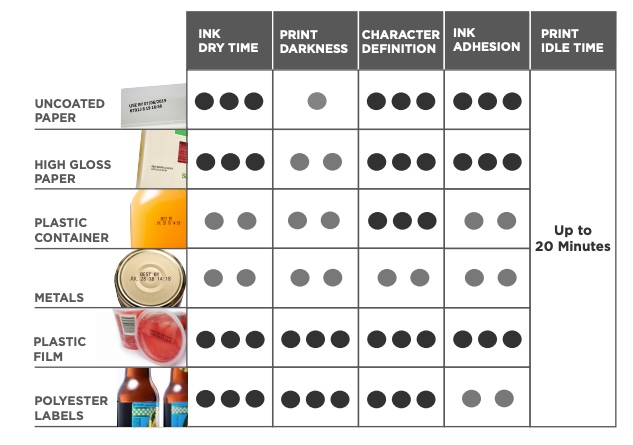

T801K INK PERFORMANCE MATRIX

The T801K ink comes in an easy to insert and change-out XL cartridge, with 40% more ink than the starter-sized, short-run ink cartridge that comes free with all Redimark marking and coding machines, including the TC12.

WATCH OUR MARKING SYSTEM IN ACTION

The Redimark TC12 thermal inkjet printer – for date, lot, and batch coding – works best on mostly flat surfaces with well-defined edges like folding cartons or paperboard boxes. The TC12 allows you to get the code exactly where you need it with an easy-to-adjust print head and specialized print features, including the ability to flip the code upside down and start printing from a set distance from the detected edge.