HOW TO CHOOSE THE CONVEYOR BELT PERFECT FOR YOUR PRODUCTION LINE

Conveyor belts are a must for Fast-Moving Consumer Goods (FMCG) manufacturers and picking the right conveyor for your specific production needs not only affects the efficiency of your line but the quality of prints coming from your inkjet date coder.

Our expert, Dean Hornby, with more than 25 years in the FMCG industry, makes it easy to choose the right conveyor by answering our customers’ most frequently asked questions about conveyor belts.

7 frequently asked questions about choosing a conveyor

1. Does the type of product I’m using on the conveyor matter?

Yes. In terms of products to be moved, it’s important to know if it’s a slippery material or something with more grip, and products with sharp edges may require different belts or conveyor materials. Also, if your product requires a washdown you will need a conveyor that can withstand getting wet. A conveyor that will be exposed to water needs to be built from different materials than a conveyor meant for dry environments and with material appropriate for the accompanying cleaning requirements including chemicals and spray pressure.

2. Is conveyor speed important?

Yes. It is important to find the right conveyor speed setting for your application that will keep up with the discharge of adjacent packaging equipment or align with the operators manual loading feed rate. Conveyor speeds can also impact the inkjet printer’s date code quality. Speeds too fast can be difficult for your operator to control and may require the product substrate to be brought closer to the print head to improve print quality. Speeds too slow may cause the conveyor to experience belt vibration or shutter. These conveyor traverse imperfections can transfer to the print quality and cause ink drop displacement. For our Redimark TC12 inkjet date coder we recommend conveyor speeds between 1 and 400 feet per minute.

3. How much energy do conveyors use?

It varies, but small table-top conveyors usually plug into a standard 110v outlet and many low-profile conveyors use light-duty motors that are very energy efficient. Larger heavy-duty conveyors that use three-phase induction motors and longer belt runs will consume more energy, typically 1 to 2 kilowatt per hour.

4. How much upkeep or maintenance do conveyors require?

For most applications, there is not much maintenance required beyond an occasional wipe-down of the conveyor belt or the bi-annual check of the conveyor belt tension. If the conveyor is run continuously in high-volume applications, the bearings will need grease applied every 10,000 hours. Bearings that lack a sufficient amount of grease will overheat and fail leading to their replacement.

5. Are conveyors safe and simple to operate?

Yes. Most conveyors are very simple and safe to operate, as long as the users follow the manufacturer’s guidelines. Conveyors can have pinch points where there is a discharge or connection to another machine or conveyor. These pinch points are best protected by the use of a transfer plate that limits the ingress of unwanted objects. In fully automated applications where the conveyor belt will start and stop by logic control, an emergency stop cord will run along the length of the belt allowing operators to stop the conveyor line manually in case of emergency.

6. What additional conveyor options should I be aware of?

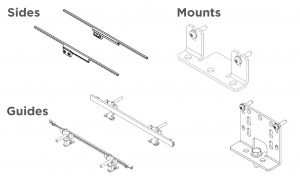

Sides, guides and mounts are additional options to consider when picking out a conveyor.

Sides or guides are used to contain the product on the belt. Sides are typically fixed to the edges of the conveyor, whereas guides are usually adjustable to a point on the conveyor belt. Mounting involves either stands if the conveyor will be on the floor, or mounts if the conveyor will be mounted atop a table or other surface. These are available in a variety of heights and configurations.

Sides or guides are used to contain the product on the belt. Sides are typically fixed to the edges of the conveyor, whereas guides are usually adjustable to a point on the conveyor belt. Mounting involves either stands if the conveyor will be on the floor, or mounts if the conveyor will be mounted atop a table or other surface. These are available in a variety of heights and configurations.

7. What if I don’t have a lot of floor space?

A low profile belt conveyor may be perfect for you. They are typically very compact and take up very little space beyond the actual footprint of the conveyor. They are available in a range of smaller sizes to accommodate a range of applications.

Bonus Question: Is there a conveyor you recommend specifically for the Redimark TC12 date coder?

Yes. QC Conveyors makes a low profile belt conveyor specially for the Redimark TC12 inkjet date coder. The AS40 Redimark Conveyor is a 6” x 36” (150mm x 914mm) includes: table mounts, a guide for the product, the motor, the mount for the printer arm, optional external product sensor mount and free shipping.